ABSTRACT: The author states the difficulties connected with the construction of very large reflectors and describes a mirror, composed by nineteen hexagonal elements. This instrument has been built and tested by the author at the Bologna University Observatory, with the mirror fixed in zenithal direction. Here the method followed in the adjustment of the elements is explained together with the description of the movements of the photographic plate. With this instrument photographs of the sky had been taken since 1935.

HISTORY - The difficulty of building large mirrors essentially consists in the fact that the thickness must be proportionate to their diameter 1 because if the disc is too thin, the glass flexes and does not retain the shape given to it by the smoothing: this leads to masses very heavy, which are handled badly during processing, and when this is completed and the mirror is placed in its final bed, supporting it on the back with equal pressure at every point is a very difficult undertaking. Finally, large masses of glass, even though the matter is very viscous, become stuffed 2 in the long run, with deformation of the reflective surface. The problem of the mobility of the mirror still remains; up to the size of five meters and the focal distance of 18 meters, the expert technicians of M. Palomar have brilliantly managed to provide that equatorial with the uniform motion required, but if it were, let's say, a mirror of ten meters in diameter, applied at the end of a movable barrel, fifty or more meters long, this would probably be a task transcendent human forces, in the current state of the art, while mirrors with motionless pieces with a diameter of ten meters will not be counted among the largest. Therefore, an era is foreseeable, in which serious thought will be given to using mirrors constantly facing the zenith;and the whole sky will be dominated with many telescopes of this type staggered in latitude. The experiments I am talking about in this booklet were performed with a motionless and horizontal mirror, which also has the particularity of being made up of many pieces or pieces, measuring an overall area of about 80 square decimetres.

At the end of the year 1935 I had already published an account 3 of what little I had then managed to do with ten trapezoidal blocks, supplied to me by Filotecnica-Salmoiraghi; the small reflecting surface (altogether just over ten square decimetres) only allowed me to convince myself that the concentration of the ten beams converging in a single vertex was feasible.

In the year 1936 the Zeiss firm provided me with ten more pieces; so that I had twenty in all, while the whole mirror with a diameter of 1.05 meters had to be made up of 80 pieces 4 . So after long tests and trials, in the summer of 1938, with the twenty pieces arranged in a circle along the fourth circle, I obtained results which, although much lower than the current ones, were nevertheless encouraging; in the autumn of that year the anti-Semitic persecution prevented me from continuing my work, which I only resumed after my liberation, in the spring of 1945.

After seven years of interruption the only optical material at my disposal were still those twenty pieces I mentioned; to these were added in the summer of 1946, another 60, worked in just over a year by our technician Aldo GALAZZI who was training in smoothing; but this hasty work did not give the expected results and we started all over again, this time facing the difficulty of a larger area to be sanded: in fact, while the first trapezoidal shaped blocks measured just one square decimeter, the new ones of hexagonal shape they measure approximately four (the circle inscribed in the hexagon has a diameter of 198 mm );their lateral shaping, carefully performed by SAIVO of Florence, which supplied the rough glass blocks, made it possible to reduce the distance between two contiguous blocks to 2 mm, whereas previously it was ten; the thickness of the blocks is three cm. The nineteen pieces placed side by side, with the interval I have said, form a roughly circular area with a diameter of one meter, as shown in perspective in fig. 4.

ACCURACY OF THE CURVATURES. - The plugs are all equipped with a spherical curvature with a radius of 20.82 meters , that is, with a focal distance of 10.41 meters; the deviation from this average value is for each tile as follows:

It means that, taken two pieces at random, the difference in their focal distances can amount to a maximum of four centimeters, or 1/250 of the average focal distance. I must say that the Zeiss company, before starting the processing of the ten pieces I mentioned earlier, and which I no longer use, declared that it could guarantee the focal distance of 10.50 m for each, only within the tolerance of ± 5 cm; in reality it was kept well below the guaranteed limit, and the gaps did not exceed ± 3.5 cm, ie at most seven centimeters, between two pieces chosen in any case.

Here, as can be seen, a difficulty arises, which does not take place in the monolithic mirror, where one does not pay attention to whether the prefixed focal distance, let's say 10.50 m, results after the packaging of 10.45 m, or 10, 55; the mirror is equally accepted as long as the surface is perfect and each of its points does not deviate from the geometric paraboloid by more than a small fraction of a micron; in our case, on the other hand, in addition to the perfection of the surface, it would be required that the focal distances of each piece were identical, while this cannot be reached easily, I am not saying within the fraction of a micron, but not even the fraction of a millimeter; and although it may seem unlikely, the results obtained from all these pieces show that the differences found in the focal distances did not prevent the star images from being comparable to those generated by the continuous surfaces of common mirrors.

Certainly pushing the processing beyond the usual and not paying attention to the time taken, as we are now doing, we will come to approach the average values of greater excursion, and we will already be happy if the waste is reduced for everyone to a fraction of a centimeter, what would be equivalent to the thousandth part of the focal distance.

I do not hesitate above an unsuccessful attempt to obtain an identical focal distance for all the pieces, using a device in which the to and fro motion of the patina was guided by two matching shapes, one concave and the other convex, with the desired radius of curvature. After the attempt failed, they returned to the classic method which consists of passing and passing over the glass surface countless times for days and days, first with the cast iron patina and then with the picea focaccia, using increasingly minute abrasives. The Ducati workshops in Borgo Panigale kindly lent me a polishing machine, with which the aforementioned GALAZZI completed the work in February 1949.

PLACEMENT OF THE DOWELS . - They are each placed on three screws which pass through the holes of a suitably perforated marble table, and integral with it by means of the nut screws; the back of the plugs bears three metal washers, corresponding to the screws: one washer is smooth, the other has a conical groove, and the third a straight groove. The weight of the dowel itself ensures its immobility and the operator, standing under the table, gives it the desired inclination, turning the screws as I will say further on. The dowels supported by the screws can be seen schematically in the lower part of figs. 1a and 1b .

CORRECTION OF THE SPHERICAL ABERRATION .- One of the many advantages, which can be obtained from the fragmentation of the reflecting area into tiles, consists in the possibility of correcting the effect of the spherical aberration, which the images would present if the adjustment led to a single spherical surface, that is when the the centers of curvature of all the pieces coincide in a single point: the images will instead be exempt from the said aberration if each circle by itself will form a single spherical surface, but the centers of curvature of the outermost circles will be conveniently higher, compared to the centers of the more internal, in which case, since the centers of curvature no longer coincide, the foci coincide instead, as in the parabolic mirror. The jump between the central piece and the first group is represented in fig. 2.

In our case (since the focal distance is 10.41 m and the width of the blocks is 20 cm), it is easy to calculate that it will be enough to raise the six blocks of the second group by 0.48 mm, with respect to the central block, and the twelve blocks. of the second round of 1.44 mm with respect to the second, to make the foci of the nineteen pieces coincide in a point, which will also be the focus of the entire mirror. This positioning in ever higher steps is done with the aid of a metal arm, as long as the radius of the mirror, and rotating around its axis; the arm is equipped at the bottom with pegs of calculated length, and the plugs are pushed by screws against the pegs, thus reaching their approximate position, which will later be rectified with optical adjustment. The arm must be kept strictly horizontal by means of a level.

In both figures, C is the collimator, T the dowel, M the marble table with the screws V. P is the bundle of parallel and vertical rays; AA 'the focal plane of objective O, containing a cross of spider threads. In fig. 1 a shows the artificial horizon B, which is removed when the verticality of the beam P is reached;

in fig. 1 b shows the plane S where during the adjustment lies a cross of spider threads, with the center in F, and later the sensitive plate. In F 'there is the real image of the cross AA', which is made to coincide with F, by turning the screws V appropriately.

If one day it will be possible, after a certain radius of curvature, to give the smoothed surface exactly the said radius within the fraction of a millimeter, it will be more practical to assign increasingly longer radii of curvature to the blocks of the outer circles, as occurs in the paraboloid, and thus the jump between group and group will be avoided, which now serves to correct the aberration we are talking about.

It will be objected that, since the differences in focal distances are of the order of a centimeter, it would have been useless to correct the longitudinal aberration, which is of the order of a millimeter: however, the correction of even a small error is never wasted and will bring all the it bears fruit when, with prolonged work, it will be possible to give all the pieces a practically identical focal distance.

Fig. 2. - Correction of spherical aberration. CB represents the central piece that occupies the lowest position; AB and CD the blocks of the 1st round, which are raised by 0.48 mm up to position A'B ', C'D', so that the focus F coincides with F '.

OPTICAL ADJUSTMENT OF THE TILES . - As I wrote in 1935, if the observer had at his disposal an immobile star at the zenith, the adjustment operation would be very simplified; in the absence of such a natural source, infinitely distant, an artificial source is used, from which it is required that parallel and strictly vertical rays emanate, like the zenith star, to be subsequently engraved on each piece, at the discretion of the observer; for this purpose, a collimating telescope C (fig. 1 ) carries in AA ', i.e. in the focal plane of the objective O , a cross of wires, indirectly illuminated by a bulb 1,the light of which is reflected along the tube of C by means of the semitransparent mirror s : the rays investing the wires therefore come out parallel from O and form the beam P; having satisfied the first requirement, the second must also be satisfied, that is, that the rays forming the beam P are strictly vertical. To obtain this with all possible accuracy, use is made of an artificial horizon B which, before starting the adjustment of the plug, is placed above it (fig.1a). Directed the collimator C towards the surface of the liquid, perfect verticality is understood to be achieved when, placing the eye in or one sees in AA ' the cross of threads superimposed exactly on its image, reflected from the surface of the liquid; with a lateral device, which is missing in the drawing, the inclination of C can be varied in all directions until said superimposition is carried out.

Once the pelvis B is removed (fig. 1b ) , the beam P strikes on the block T which in reflecting it generates in a point F ' the real image of the cross lying in AA'; if F ' does not coincide with point F (previously designated as the focus of the entire mirror, and lying on the meeting point of another pair of crossed threads), acting on the screws V , the plug will be considered to have been adjusted, when F' has been made to coincide with F;the operation is subsequently repeated on the other pieces after which the entire mirror will be able to converge in a single and not deformed point, not only the vertical beam just considered, but beams in any case inclined with respect to the vertical up to the limit angle experienced by 49 '30 ". The approach of the F' to F, by the action of the screws, is observed with the eyepiece L: the point F lies exactly in the focal plane S, the F ' with a very large approximation (see the table). adjustment method does not present difficulties when certain expedients dictated by experience are used.

Two close-knit people, one working on the screws V, the other on the eyepiece L, manage to fix a piece in a few minutes. The lower operator has to do is subsequently apply a key to the head of the screws, electrically controlled by the upper operator, who has the eye in L and turns the screws according to his talent, until point F ' is from him . judged to coincide with F.

The current situation of our mirror is very unfavorable to adjustment, due to the fact that the colored water of the artificial horizon, located as it is 40 m high on the road floor, is affected by the oscillations of the Tower, especially during the day. we therefore prefer the adjustment performed in the second half of the night. All nineteen pieces are adjusted by trained people in just over two hours and lasts unaltered for at least a week. In the new plant, which I hope to complete, the mirror and the water basin will be located a few meters below the road level, and protected from any shaking from city traffic.

Before the definitive adjustment I mentioned, another one is made with the help of the convex caliber: this is a 23 cm diameter round disc with very approximation of the same curvature as the blocks, but with the opposite sign. By superimposing it on the concave surface of the piece, fringes are formed, the number of which must be identical for each piece examined. Now, covering two contiguous pieces of the same group, these are conveniently considered to be in place, when the half fringes of one are the continuation of the half fringes of the other, and we proceed in this way, couple by couple, until the circle is exhausted; naturally the jump of the step from one group to another allows this sort of adjustment, only within the same group, and not between contiguous blocks of different groups.

Much more precise and quicker would be the adjustment by placing the illuminated threads in the center of curvature of the mirror instead of in the focus; that is, to be more exact in the centers of curvature of the various circles, which in our case are distant from each other as we have seen by 0.48 and 1.44 mm; with this the inconvenience of the mobility of the artificial horizon would be eliminated, and only the superimposition of the illuminated lattice and its real image, reverberated by one piece after another, would have to be taken care of. With this, however, the masonry would be magnified, because it would require a tower twice as high as the focal distance, and instead of two floors there would be three: the upper one for adjustment; the medium for the sensitive plate, the lowest for the mirror. In the new system I propose to experiment with this adjustment method as well.

Fig. 3 - The mouth of the well on the top of the tower. In the center, the slide on which the plate holder runs and the articulated shaft that turns the perpetual screw. On the front the motor apparatus integral with the shaft and the automatic control device, illustrated in figs. 6 and 7.

Fig. 4 Marble table with nineteen anchors placed on the screws; diameter of the dowels cm. 20; diameter of the whole one meters. In the thin white margins inside the surface of the mirror the jump of mm is visible. 0.48 between the central piece and those of the 1st round, and the jump of mm. 1.44 between the second and third round. The upright and upside-down image represents the dowel smoothing device mentioned above.

Distance between the plane of the sensitive plate (fig. 3) and the vertex of the mirror (fig. 4) 10.41 meters.

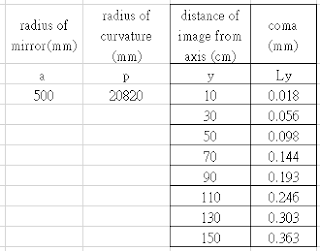

COMA. - The star image deformed by the coma is symmetrical with respect to a straight line joining the image itself with the center of the plate (or more precisely with the point of the plate intersected by the axis of the mirror); the length of this image in the sense of the joining is given by the expression :

Ly = (a / p^2 ) y (3a + 4y)

where y is the distance of the image from the axis, a the radius of the mirror (here 500 mm); p the double focal distance (here 20.82 m). I report in the following table the values of L y for the different y :

and from here it can be seen that, traced on the plate a circle with the center on the mirror axis and with a radius of 10 centimeters, all the star images included therein show a deformation, depending on the coma, of less than two tenths of a mm; and even if the said radius is up to 15 centimeters, the deformation barely exceeds one third of a millimeter, and is lost in the diffusion disk.

To get an idea of the quality of the images, look at the photographic reproduction on sensitive paper (fig. 5): it was printed by contact with the original plate No. 650, exposed for 6 m 15 s , on the evening of 4 August 1949 .

Fig. 5 - Reproduction by contact of the original plate N. 650 photographed on the evening of April 24, 1949. Duration of exposure 6 m 15 s . The largest star at the bottom edge of the map is BD 43 ° 3581, of ninth magnitude, which culminates 28 'south of the zenith of the Specola. The faintest stars visible on the plate are between the 15th and 16th magnitudes. Scale: 1 '= 3 mm.

The large star visible at the bottom edge of the card is BD 43 ° 3581 of ninth magnitude. With a magnifying glass it will be easily seen that all the images up to the edges and corners are equally round, and think that the lateral stars (along the longest side of the rectangle) were photographed while they were, the ones at the beginning and the others at the end of the pose, at a distance of almost 15 centimeters from the axis of the mirror; in fact, since the duration of the laying was 6 m 15 s , equal to a trajectory of 203 mm, the 45 mm corresponding to half of the short side of the slab must be added to half of this value, i.e. 146 in total, 5 mm. Thus it can be said that the useful field of this mirror would cover a plate of nine by thirty centimeters, its long side being oriented in the direction of the meridian.

Since thirty centimeters in the focal plane are equivalent to 1 ° 40 ' of declination, with a series of six mirrors equal to this one, spaced 185 km apart, to be counted in the sense of latitude, all ten degrees of the zenith sky of Italy would be dominated.

Another proof of the degree of concentration of the 19 superimposed images comes from the separation of the double stars; for example. the triple star ADS 4765 which in 1908 had a distance between the major components of 6 "85 appears clearly separated on plate No. 838 by a glossy space, that is to say, in the narrowness of a third of a millimeter (since a millimeter is equivalent to 20 ") are the two disks and the clear space that divides them. Thus in plate No. 805 the double ADS 4057 between the components of which a space of only 5 "6 is interposed, presents, even if a clear interval is not visible, the two disks just superimposed on the edges, while their centers are not far from each other. more than a quarter of a millimeter.

MOTION OF THE SLAB IN THE FOCAL PLANE. - The immobility of the mirror forces us to follow the rotation of the sky with a movable plate in the focal plane; the chassis must therefore cross the said plane with the speed of the stellar motion; this is provided by a direct current electric motor, powered by a 12 V battery. I will tell later how uniformity of motion is achieved. The trajectory of the stars, projected into the focal plane, is generally a conic one: a circle, if the horizontal mirror has one of the poles of diurnal rotation at its zenith; a straight line, if the mirror lies at the equator, an ellipse, between the latitudes 90 ° and 45 °; a hyperbola between 45 ° and 0 °; and for j = 45 ° a parabola, which is practically the case of Bologna ( j = 44 ° 29 '52 "77 ). It was therefore a question of having the chassis describe the said parabola, whose parameter, as you can easily see, is f, if f is the distance focal length of the mirror; therefore the radius of curvature in the vertex = f. Considering the considerable length of f = 10.41 meters, it is legitimate to confuse the curvature of the parabola with that of the osculating circle, not only in the vertex, but also in a neighborhood of about ± 10 cm A 10.41 long iron lattice pendulum was therefore built meters and secured at its free end a carborundum grinding wheel, this, describing the desired curve with the oscillation of the pendulum, served to cut two metal shapes, one concave and the other convex. The concave shape is fixed in the focal plane with the appropriate orientation, the other carrying the chassis moves along the first, without ever moving away from it, by virtue of a spring that keeps them close together; so the star image never leaves the point of the plate occupied since the beginning of the exposure, and the one and the other travel together the same way for over six minutes which lasts the pose, as evidenced by the unique images and perfectly round.

This unchanged adherence of the star image to the same point of the plate is reached only when the chord of the circular metal segment, making up the shape, is rigorously oriented in the east-west direction; otherwise the image becomes a small straight segment parallel or oblique with respect to the meridian direction, depending on whether the speed impressed by the motor is equal to the calculated one, or not. The rigorous orientation in the east-west direction is obtained by photographic means, first discovering the stationary plate, until the star has left a short trace on it; then the plate is made to walk, so that it accompanies the star in the longest possible time, and the star imprints a point-like image on it; finally, the still uncovered plate stops, to obtain a second trace of the star:if one of the traces is the exact continuation of the other, the orientation is perfect.

It is easy to calculate that for j = 44 ° 29 '52 "77 and for f = 10.41 meters the speed of a star of this declination in the focal plane is one millimeter every 1 s , 852 seconds of sidereal time. it is maintained by the motor headed by a mechanism of toothed wheels, the last of which is integral with a perpetual screw, having a pitch of two millimeters, and makes it rotate on itself by one revolution every 3 s , 704.

Thus the nut screw that embraces it proceeds in the focal plane and with it the chassis holder, at the calculated speed. It is true that the star, and the frame forced by the shape, describe a circular segment while the lead screw proceeds in a straight line, but the difference between the arc and the string is just 0.003 mm in the 20 cm stretch, covered in 6 m 15 s . The chassis holder and motor are shown in fig. 3, and the latter is also discussed in the next chapter.

AUTOMATIC MOTION CORRECTION. - No matter how uniform the current administered by the accumulators is, it certainly fails to make the motor shaft turn by that invariable number of revolutions which are required, for the star and the plate to proceed in absolute preservation. Nor, on the other hand, could it be thought of following a guiding star and making the calls in the ordinary way if necessary, because, by moving the plate in the center of the field, the observer's body, intent on following the star, would have subtracted too much light; and wanting to operate in the Newtonian focus this instrument would have become too complicated, which is only a model, built with the few means available to the Specola. Here the talent of the mechanic Irio GRASSI came to the rescue ,former technician of the Astronomical Station of Loiano, who devised the automatic correction device which responded perfectly to the purpose, and which I am about to briefly describe. The two discs A and B (figs. 6 and 7) look at each other without touching, and are ideally coaxial; however a conductor c, integral with A, touches the coils of a resistance r , integral with B: the disk A (stressed by the motor through the reduction mechanism R ) would make one revolution in one minute of sidereal time, if the absolutely uniform speed by the motor; disk Bit is moved by a clock and also completes one revolution in one minute of sidereal time. We are sure of the motion of B , during the short time that the installation lasts, that is 6 m 15 s ; it is therefore a question of obliging A to keep its position with respect to B unchanged during all six turns, which is obtained by means of automatic correction: if A advances with respect to the exact time, the conductor c moves above the resistance r (fig. 6 and 7) excludes one or more turns; thus the engine retards and the acceleration of A ceases; vice versa, if A delays, cmoving in the opposite direction increases the number of turns, and the motor accelerates, and so on. The fig. 6 shows the circuit diagram and fig. 7 the two discs in perspective.

A similar device was also mounted in Loiano to replace the Zeiss regulator, which was not saved from destruction during the war; there, however, the observer follows the guide star and makes the necessary corrections with the electric controls; however, the automatic correction exempts the observer from the bondage of continuous attention.

The roundness of the stellar images is an infallible sign of the uniformity of the motion: a delay or a surplus of one second in the six minutes that the pose lasts would intolerably lengthen the image by half a millimeter, in the sense of parallel.

MAKING OF THE TILES MIRROR .It goes without saying that it will be more and more practical to pack one-meter mirrors, like ours, in a single piece; but, wanting to go to very large diameters, the need for splitting into pieces is evident, and the imagination can transfer us to a future, perhaps not very far away, in which wells of hundreds of meters deep will be dug, to place mirrors in pieces of hundreds of square meters. In order not to leave Italy, there are overhangs here ready and suitable for such installations, and I want to mention two of them: one artificial, and one natural, that is the well of San Patrizio in Orvieto, and the Grotta di Castellana (Bari) . Already the Superintendency of Monuments of Umbria had taken into consideration my request which was not followed up, above all for financial reasons: there, however, there would be to fight against the excessive humidity of the bottom,perpetually covered by water, which would damage the silvering of the plugs: the aluminised surfaces would suffer less damage and there is no shortage of measures to combat the inconvenience of humidity, in which case the well, with its sixty-three meters deep and seven meters of free opening, it would represent the ideal framework for a mirror five meters in diameter, and sixty meters of fire. The bottom is accessed, as is known, by the twin staircase carved into the rock, which is one of Sangallo's masterpieces.it would represent the ideal backbone for a mirror five meters in diameter, and sixty meters of fire. The bottom is accessed, as is known, by the twin staircase carved into the rock, which is one of Sangallo's masterpieces.it would represent the ideal backbone for a mirror five meters in diameter, and sixty meters of fire. The bottom is accessed, as is known, by the twin staircase carved into the rock, which is one of Sangallo's masterpieces.

Equally suitable for the purpose would be the main cave of the Castellana 6 Caves , which measures 45 meters deep, and receives light from the top of the vault, through a natural elliptical orifice, with the major axis of 14 meters and the minor of 11. Here, due to the more abundant circulation of the air, and the free access to the sun's rays, there is no drawback of humidity. If you want to remove the debris of the bottom, composed of waste poured into the chasm and accumulated since time immemorial, you could

get to the primordial floor of the cave, increasing its height by 15 and more meters. Thus the mirror lying on the bottom could measure nine meters in diameter and about seventy of focal distance, rising a little outside. The very worthy director of those caves prof. Franco ANELLI has arranged the underground access, by having an oblique lateral tunnel excavated, which can be crossed by a very comfortable staircase, and the installation of a funicular is being studied, which will exempt the

visitor from overcoming the not slight difference in height on foot.

However, the telescope with dowels, like any other precision instrument, would need very selected materials as are not those that were used to build this first specimen, starting with the glass, ending with the support screws, and the marble table, which they should have been made of pyrex, invar and porcelain respectively, with the benefit of precision and saving time and effort so that any defects in the method can be discovered, when those dependent on the material have been eliminated.

Finally, I want to mention here an advantage of this instrument which would be profitable if instead of the plate, to be changed every six minutes after installation, a perpetual film was replaced, unwinding and wrapping on two opposite rollers, and animated by the prescribed speed. In this way one would obtain on a single tape the photograph of as much part of the zenith sky, how long the night is, and it is no one who does not see the usefulness of this uninterrupted documentation of the history of the sky, who will, on the other hand, require from the operator no more than an occasional surveillance.

I will not close my speech without remembering the valuable help that came to me in this enterprise not only from the staff of the Specola, but also from strangers, such as the astronomer LACCHINI of the Trieste Observatory, the surveyor. FERRI of the Institute of Geodesy, and the mechanic GRASSI of the Institute of Physics, who were my patient collaborators of the first hour, since the year 1934 ; a special mention deserves the Specola technician Aldo GALAZZI ,to whose intelligent effort it is due in large part if the idea of the mirror with pieces could be translated into reality; he smoothed all the pieces from the raw state to the finished finish, performed almost all the mechanical and electrical devices and finally showed himself to be a master of adjustment, even if he had no right hand.

Optical spec:

total diameter: 1 m

focal length: 10.41m

focal ratio: r/10.4

segments: 19

bigger 1952 version:

total diameter: 1.8 m

focal length: 10.4m

focal ratio: f/5.7

segments:61

plate scale (for photo film): 20"/mm

resolution(theoretical): 0.05"/mm

individual segment resolution(measured):0.5"/mm (?)

overall mirror resolution(measured):5"/mm(?)

留言

張貼留言