The original proposal had both sets of the Self-Propelled Modular Transporters spaced apart. Starting on the south end (FIU) the first rig was planned to be positioned directly under the south end of the span & the next rig 24 ft to the north. At the opposite end, north (Sweetwater)/Pylon, one rig was again to be positioned directly under the north end of the bridge with the final rig 27 ft to it's south. As it turned out this plan was too wide for the road way and they may have encountered a hiccup with uniformly supporting the bridge when driven over the center divider. It looks like they still had trouble driving over the center divider, even with the tandem Self-Propelled Modular Transporter arrangement. They stopped half way across and just sat their for a long time. Since the Self-Propelled Modular Transporter was no longer under the ends of the bridge, I wonder if they decided to PT the No. 11 Truss, with the intent to De-Stress the truss once the bridge was in place. It sure seems like it took a lot longer than 6 hours to position the bridge. It looked close to midday when they we finished

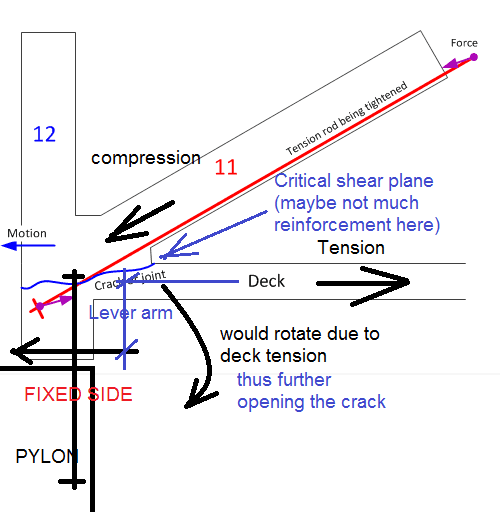

In any truss node, quite a lot is happening structurally. The vertical forces in the diagonals will be in balance: in the drawing above, if the left-hand diagonal at the node is in compression, the vertical component of that compression will be matched by a vertical component of tension in the right-hand diagonal. The sum of the horizontal components of force in the two diagonals is balanced by a change in horizontal force between the left-hand and right-hand elements of the horizontal member, which on the drawing represents the roof slab.

As this is a prestressed structure, there will significant compressive forces in the node, with high localised stresses due to the proximity of the stressing bar anchorages. Taken together with the change in forces to be accommodated through the node, this is a highly complex design element, and one which would have been much easier to design in steel rather than in concrete.

The first lawsuit filed over the pedestrian bridge failure at Florida International University that killed five motorists and one worker pulls together details from the unusual amount of public information and images available about what occurred. It suggests that post-tensioning triggered the failure that brought down the structure.

According to the lawsuit, the March 15 collapse, over a road separating the campus from the city of Sweetwater, occurred while a crew was post-tensioning bars in a diagonal member at the north end of the concrete truss that was the bridge’s main element. The post-tensiong compressed the diagonal so that it overstressed a joint in the top cord, the lawsuit claims, triggering hinge failure at a connection in the lower cord and resulting in the catastrophic failure of the rest of the 174-ft-long structure.

|

Enlarged dash cam video with letters pointing to connections that allegedly failed during post-tensioning operation on truss.

|

happypontist

eng-tips forum

August 2018 update:

The deadly FIU bridge collapse suffered from design flaws, say Fed

Although the evaluation is ongoing, the assessment has determined that errors were made in design of the northernmost nodal region of the 174-foot-long span, where two truss members were connected to the bridge deck. These design errors resulted in

(1) overestimation of the capacity (resistance) of a critical section through the node comprised of diagonal member 11 and vertical member 12; and

(2) apparent underestimation of the demand (load) on that same critical section.

Additionally, the FHWA evaluation determined that the cracking observed in the node prior to the collapse is consistent with the identified errors.

2 page report from NTSB

NTSB press release

The unconventional placement of diagonal supports in an uneven zig-zag pattern along the bridge produced a complex structural web with a glaring weakness at a key connection point, apparently overlooked by designers at FIGG Bridge Group, say three independent structural engineers who reviewed nearly 2,000 pages of calculations for the bridge at the Miami Herald's request.

miami herald

miami herald 2

The experts consulted by the Herald said the cracks were concerning enough that they should have prompted a stop to work on the bridge and a redirecting of traffic below the span for a thorough evaluation, something that available records suggest did not happen.

Instead, after a morning meeting of FIU’s team called to discuss the cracking, a crew was sent out to tighten steel support rods that ran inside the Number 11 strut — possibly an effort to close the cracks, the independent experts say. Traffic continued to flow below the span, which collapsed without warning while that “post-tensioning” work was going on, killing one crew member and crushing motorists stopped at a red light beneath.

some update report from NTSB below:

"the chief probable cause" was "the design by FIGG Bridge Engineers",

and that "every company, institution and agency involved in the project

was partly to blame for the bridge collapse

Feds fine contractors

eng-tips

nbcmiami

留言

張貼留言